- Home

- About Us

-

Products

-

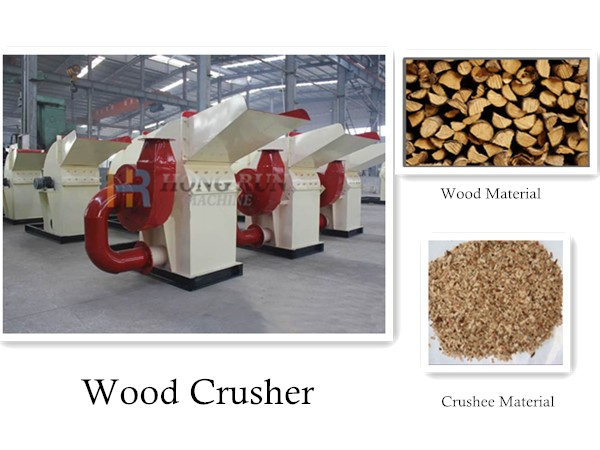

Crusher

- Hammer Crusher

- Tree Branch Crusher Machine

- Wood Chip Crusher

- Sawdust crusher

- Building Template Crusher

- High Efficiency Fine Crusher

- Scrap metal crusher

- Wood Log Chipper Machine

- Mosquito coil powder grinding machine

- Wood powder grinding machine

- Charcoal Pulverizer Crusher

- Charcoal Powder Crusher

- Wood Powder Crusher

- Coconut Shell Shredder

- Wood Trees Branch Grinder

- Agricultural Stalks Crusher Machine

- Portable Chipper Machine

- Hay Cutter

- Scrap furniture board crusher

- Mobile Crusher Machine

- Sawdust Extruder Machine

- Dryer

- Charcoal Moulding Machine

- Carbonization Furnace

-

Auxiliary Equipment

- Automatic Powder Packing Machine

- Food& Charcoal Briquette Packing Machine

- Portable Handheld Electric Bag Sewing Mac

- Permanent Magnetic Iron Separator for Iro

- Charcoal Mixer

- Belt Conveyor

- Smoke Collection Device

- Rotary Screen

- Wire Mesh Belt Conveyor

- Gasifier And Purifier Dryer

- Spiral Conveyor

- Dry mixer

- Vibrating Screen

- Sawdust Distributor

- Micro Powder Grinding Mill

- Mining Equipment

-

Crusher

- Production Line

- News

- Trading Notes

- Contact Us