Welcome to HONGRUN Machinery

Continuous Carbonization Furnace

Continuous carbonization furnace makes charcoal from wood, sawdust, bamboo, coconut shell, rice husk, stalk, agro wastes and many other biomass materials. How to Make Charcoal from Biomass Materials?

Learn More

The charcoal can be turned to charcoal briquettes with different shapes by charcoal briquette machines.

Related Product :

Charcoal Briquette Machine

Continuous carbonization furnace can be used for recycling electronic waste& scrap metals, such as aluminum capacitor recycling, circuit board recycling, waste wire recycling, and scrap metal paint removing.

Environmental protection continuous carbonization furnace adopt gasification carbonization principle, adopt advanced smoke-free environmentally friendly carbonization process: the entire equipment from the gasification system (gasifier, spray tower, dust collector), purification system Leach, oil and water separator, filter), carbonization system (carbonized host, screw feeder, screw feeder, cooling machine, conveyor, finished cooling warehouse), control system (control cabinet), the entire carbonization process is automated production, automated operation.

Hongrun energy-saving environmental protection continuous carbonization machine has two significant advantages: First, the host capacity, high carbonation rate, strong production capacity, per hour carbonized rice husk about 1 ton; Second, low cost, cost Low practicality, to meet the initial entrepreneurial investment benefits of small objective requirements.

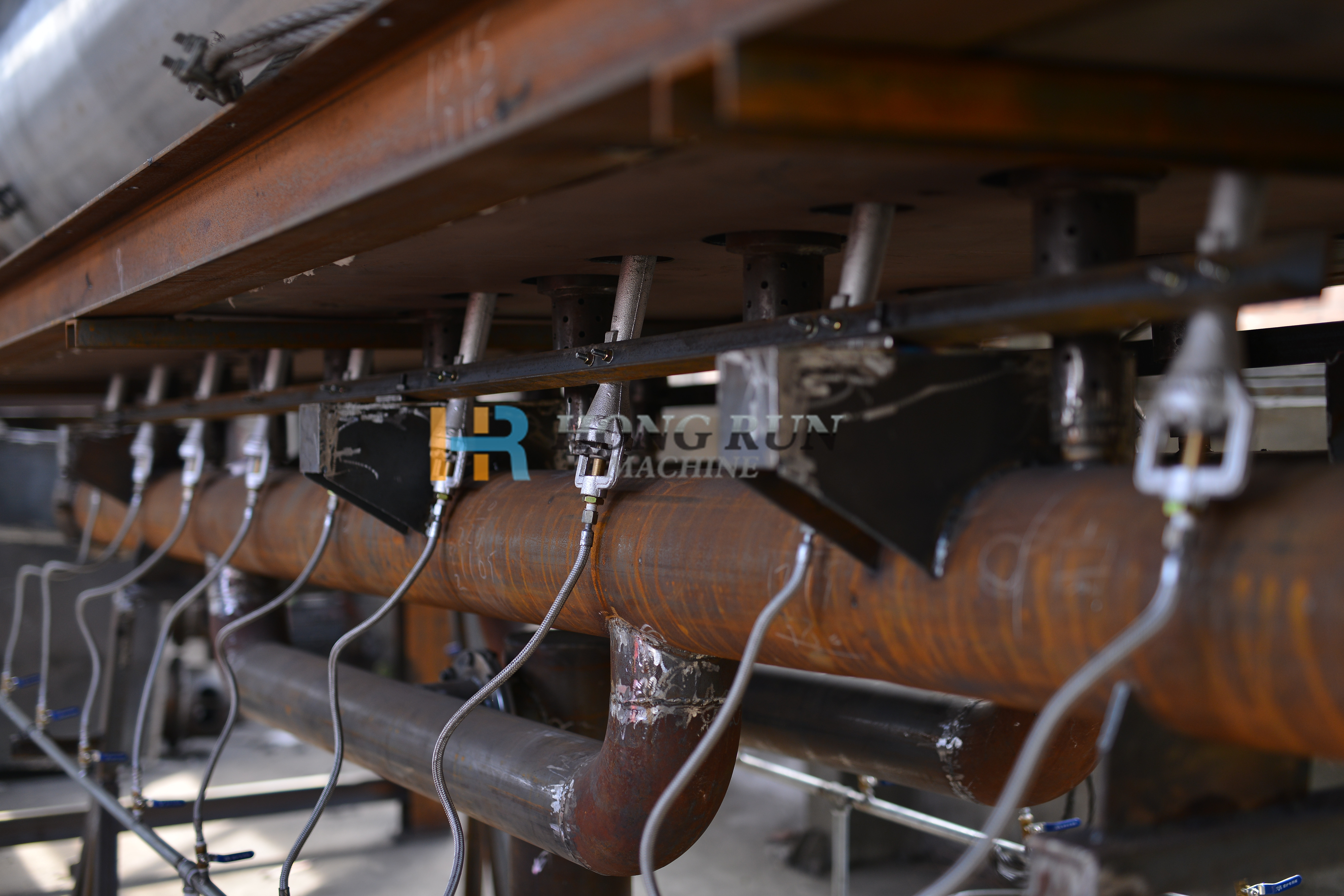

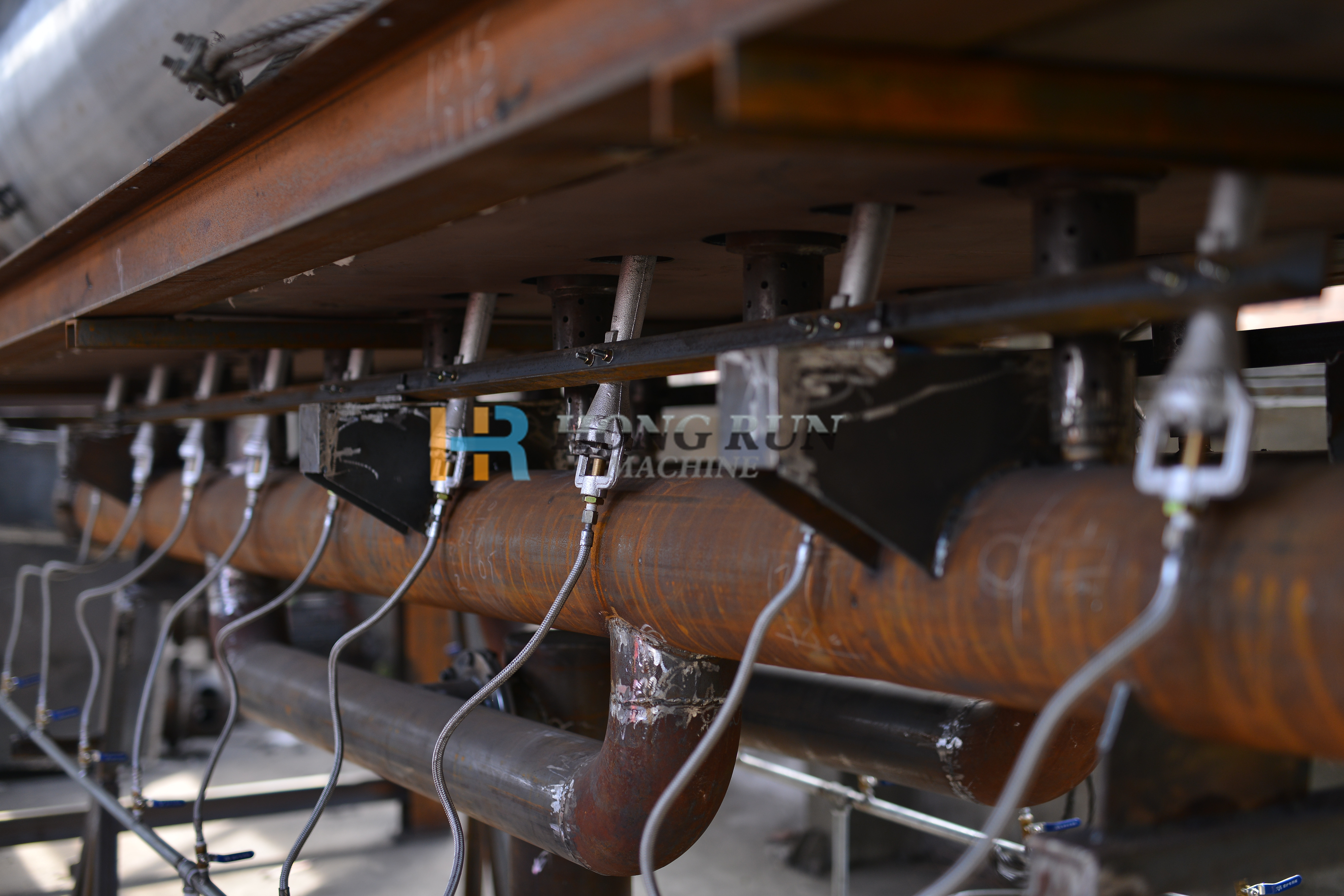

Continuous carbonization furnace belongs to an external heating drying and carbonization integrated machine. The flue gas generated in the entire production process is self-utilized, and the exhaust gas passes through the flue gas treatment device in the photo below. The whole process does not pollute the environment after technical improvement.

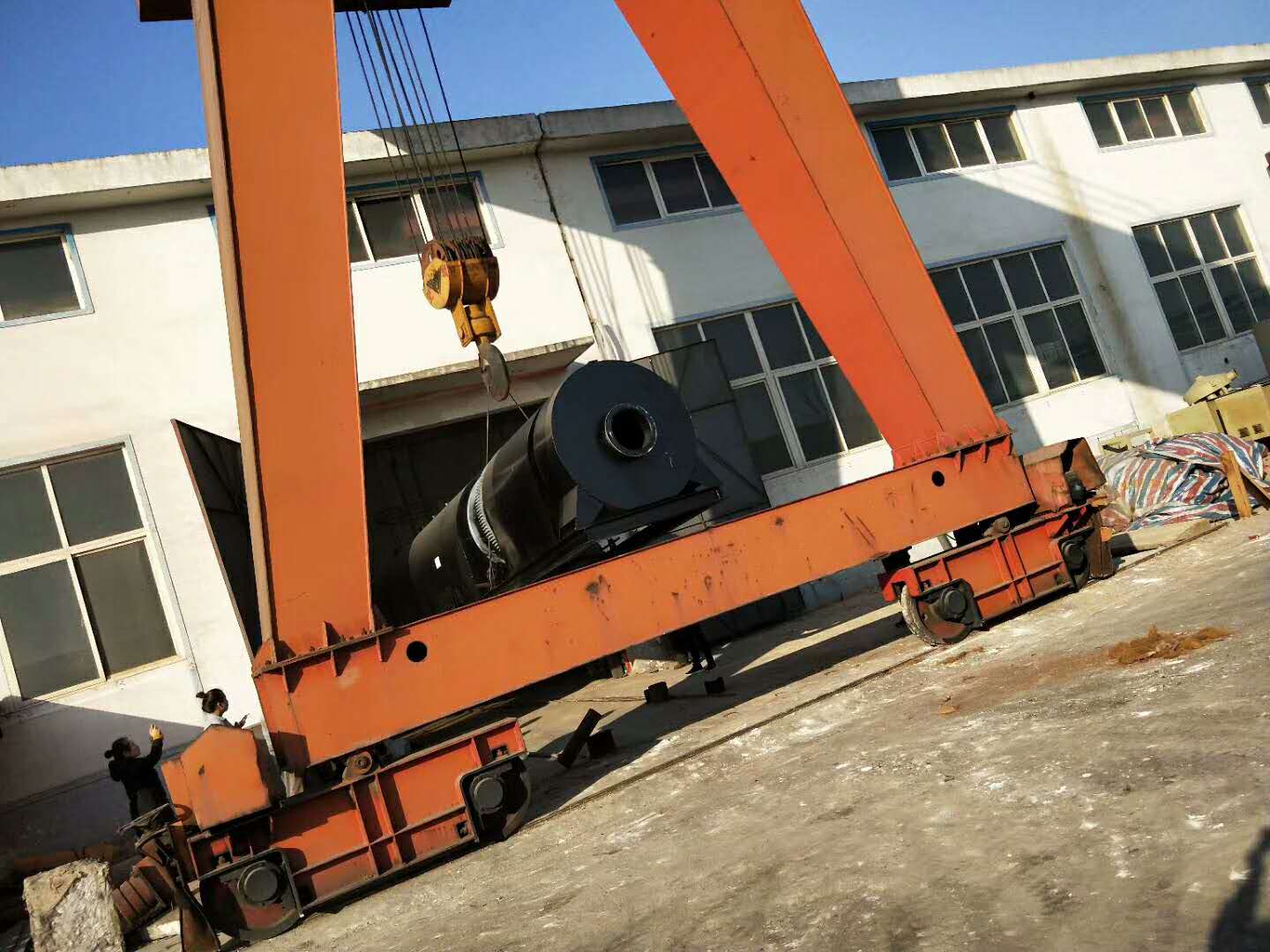

Horizontal Carbonization Furnace,

easy to operate, various models with different capacity.

Hongrun Machinery mainly produces charcoal making production line machinery and equipment, including wood crusher, carbonization furnaces, drying equipment, charcoal briquette machines, etc, which can successive deal with material until finishing molding charcoal products. The raw materials of finishing molding charcoal products come from wood, coconut shell, bamboo, straw, grain shell and so on.

Welcome your inquiry! When you send us E-mail, please tell us the machine name you are interested and the raw material you have, so that we can recommend you with suitable machine and good price, thank you. elcome your inquiry!

Below photo is the upgraded version of double-layer continuous carbonization furnace. The upgraded version of double-layer continuous carbonization furnace can also be used to recycle electronic waste& scrap metals, such as used beverage cans (UBC) paint removing.

The advantages of the upgraded version of double-layer continuous carbonization furnace:

The upgraded version of the continuous carbonization furnace with double layers of rotating inner tanks, the material is first heated in the first layer inner tank for a period of time, and then rotated into the second layer inner tank, so that the material is carbonized more fully and fast. In addition, the outermost three-dimensional square furnace body shell is covered with three layers of rock wool inside, so that the continuous carbonization furnace is more heat preservation and heat resistance.

The combustible gas produced by the double-layer continuous carbonization furnace during the carbonization process will pass through two spray pipes and two condensers through the pipeline, and finally enter the internal furnace again to help the stove continue carbonization. At this time, the external heat source can be removed. Such a design not only allows the flue gas to be purified well, but also enables the combustible gas to be recycled, which is more energy saving and environmentally friendly.

Welcome your inquiry! When you send us E-mail, please tell us the machine name you are interested and the raw material you have, so that we can recommend you with suitable machine and good price, thank you.