working principle

Dry powder mixer, also known as dry powder mixer work mixed, the machine material by the two opposite directions of the rotor, the compound movement, the blade of the material to drive along the machine wall counterclockwise rotation, on the one hand to bring the material flip , In the two rotors overlapping overlapping weight loss zone, in this region, regardless of the shape of the material, size, and density, can make the material floating in an instant weightlessness, which makes the material in the machine slot to form a full range of continuous loop flip, Interlacing shear, so as to achieve fast and gentle mixing effect.

Dry mixers are standalone mixers that work individually with conveyors, storage tanks, and electronic gauge automatic packers (for valve pockets saving 3-4 workers and significantly increasing productivity) One-stop production, is the upgrading of traditional production technology products.

Dry powder mixer is adapted to a variety of dry powder, fine granular materials mixed (such as: putty powder, plaster, dry mortar, colored cement, all kinds of mineral powder, chemical materials, organic fertilizers, etc.).

Work characteristics

In addition, the material inside the machine under the action of blades, both circular motion, but also axial movement, according to the movement of materials produced convection mixing, shear mixing and diffusion mixing; according to the mortar need to add about 10 mm of poly Benzene fiber, not easy to disperse when stirring this feature, we have installed a set of flying knives, through high-speed rotation, the knot of fibers dispersed, to achieve the desired effect.

Performance characteristics of the structure

Mixing of dry mixers requires that all participating mixes be distributed evenly. The degree of mixing is divided into ideal mixture, random mixture and completely mixed state. The degree to which the various materials are mixed in the mixing machinery depends on the proportions of the materials to be blended, the physical state and characteristics, the type of mixing machinery used and the duration of the mixing operation.

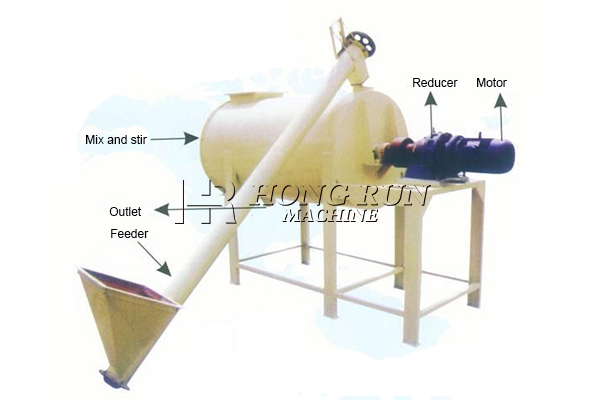

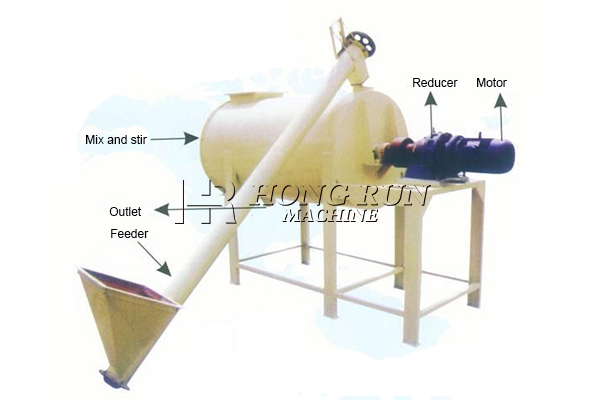

The main components of the equipment

Dry mixer main body, motor (power supply is 380V, 50Hz three-phase AC) .Among them:

Dry mixer 1000 (motor output 3KW)

Dry mixer 2000 (motor output 5.5KW)

Structural features

1, The dry mixer is a horizontal barrel. The inside and outside two-layer spiral belt has a unique structure, stable operation, reliable quality, low noise, long service life, easy installation and maintenance, and a wide range of stirrer structures. Functional mixing equipment.

2, mixing speed, high mixing uniformity, especially sticky, spiral belt can be installed on the scraper, but also to adapt to thick, paste-like mixture.

3, under the requirements of different materials mixing (special materials must be cleaned after each mixing), using different spiral belt structure, can be heated, dry jacket type.

Use care

1, Installation: The mechanical stability, installed machine feet, pad flat, so that machinery can operate freely.

2, Before using, add the oil to the fueling station, and then perform the no-load operation, check whether the fasteners are loose, the electrical is normal, the machinery is operating normally, and repair and debug if there is any abnormality.

3, the feeding port to the top, open the feeding cap feeding, the feeding amount can not exceed the required volume, and then close the feeding cap, start the machine to run, en route if found abnormal, you must stop checking.

4, after get off work or change the species must hopper inside and outside rinse.