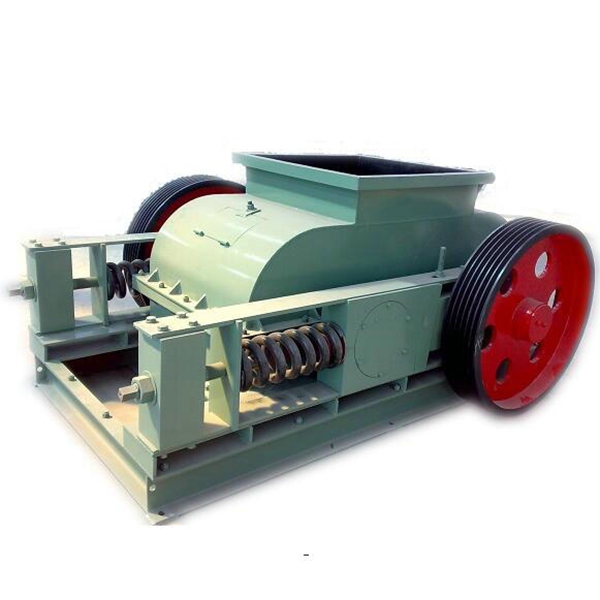

Introduction of Jaw Crusher:

Jaw crusher is necessary equipment for ore crushing. Jaw crusher mainly applies for primary and crude crushing of all kinds of hard rocks and block materials. Jaw crusher has been widely used in the fields of building materials, metallurgy, ore, water conservancy, construction, and hydropower, etc. Jaw crusher has great advantage on structure and performance. It is a very popular device on the market.

Jaw crusher, your preferred primary crusher, is used for coarse crushing and fine crushing. Jaw crusher has features such as large crushing ratio, uniform product size, simple structure, reliable work, easy maintenance and economical operation.

Application of Jaw Crusher:

Jaw crusher is suitable for crushing materials with compressive strength no more than 320 MPa, such as metal and no-metallic ores, stone and sand, river pebble, calcite, coal gangue, cement clinker, basalt, quartzite, ferrosilicon, construction waste, etc.

Jaw crusher can be widely used for basalt stone, bauxite stone, calcite ore, chromium ore, clay ore, copper ore, dolomite stone, feldspar stone, gold ore, granite stone, gravel, gypsum stone, iron ore, kaolin ore, lead ore, limestone, manganese ore, pebble ore, quartz stone, shale ore and other stone crushing.

Specification of Jaw Crusher:

Specification of Jaw Crusher:

The largest feed size: 125-1500mm

Production capacity: 5-1000t/h

Equipment weight: 0.8-150.6t

Features of Jaw Crusher:

Features of Jaw Crusher:

1.High ratio of crushing;

2. Homogeneous final grain size

3. Simple structure

4. Reliable working condition

5. Easy maintenance

6. Low operating cost

Structure of Jaw Crusher:

Structure of Jaw Crusher:

1. Jaw crusher use advanced manufacturing technology; adopt high wear-resistant materials.

2. The more advanced moving hub assembly makes jaw crusher more durable. The moving hub assembly is made of high quality steel castings and is driven by two large cast steel flywheels, reduce vibration effectively and make machine work stably .In addition, heavy eccentric shafts are also processed using forged billets. All these make jaw crusher have superior reliability.

3. The bearing seat adopts an integral cast steel structure, and the integral cast steel bearing seat can ensure it perfect fitting for the crushing frame, and greatly enhanced the radial strength of the bearing seat. However, the split bearing does not have this advantage.

4. Adopting finite element analysis technology, jaw crusher has higher strength.

5. The crushing chamber adopts symmetrical “V” shape structure; so that the actual feed port width is consistent with the nominal feed port width.

6. Discharging outlet adjustment is faster and more convenient. Jaw crusher is equipped with wedge discharge adjusting device. This device is simpler, safer and faster than the old gasket adjusting device.

7. Larger bearing specification and higher bearing capacity. Jaw crushers are equipped with larger and more durable eccentric shaft bearings than other crushers of the same size, the higher bearing capacity and effective labyrinth seals greatly extend the bearing life.

8. Jaw crusher adopts tooth guard plate, increasing the effective length of jaw plate, higher yield.

Releated Products:

Releated Products:

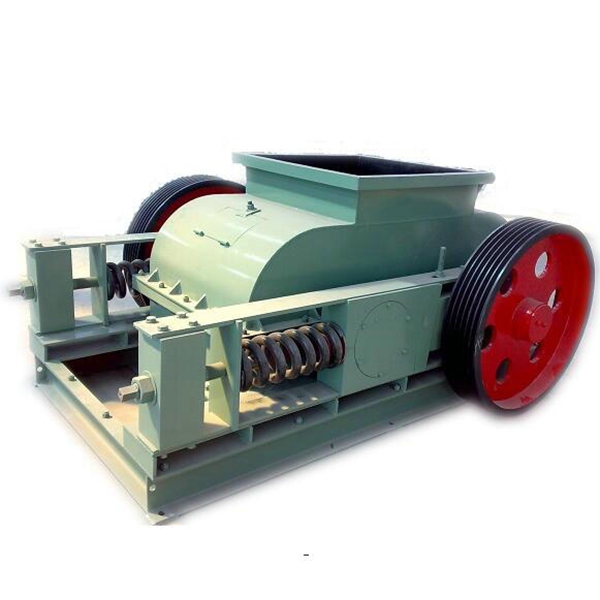

Double Roller Crusher