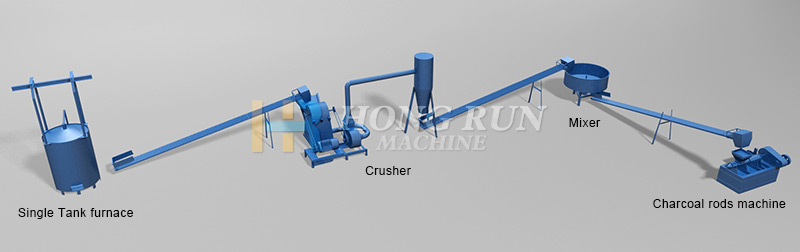

On Oct 25, 2025, Hongrun charcoal briquette production line exported to Ghana. The charcoal briquette production line includes carbonization furnace, charcoal crusher, charcoal mixer, charcoal briquette machine.

Hongrun charcoal briquette production line can carbonize biomass materials into charcoal. The biomass materials can be shaped briquettes or shapeless material such as wood logs, wood strips, bamboo, coconut shell etc.

There are several steps to make biomass materials into charcoal briquettes.

1. Put biomass materials into carbonization furnace for anaerobic carbonization, and the organics, tar and moisture contained in the biomass are all carbonized during anaerobic firing process. Get charcoal.

2. After cooling, crush the charcoal into charcoal powder.

3. Then transport charcoal powder into grinding wheel mixer for fully mixing and wetting.

4. Put the mixed charcoal into different charcoal forming machine to get charcoals of wanted shapes.

The general charcoal briquette production flow can be Raw Material Carbonization--Charcoal Crushing--Mixing---Charcoal Briquette Forming (shapes: balls, rods, tablets, etc.). So the charcoal making equipment in the charcoal briquette production line includes Carbonization Furnace--Charcoal Crusher--Charcoal Mixer --Charcoal Briquette Machine and other auxiliary equipments.

Hongrun charcoal making production line includes crusher, dryer, carbonization furnace, charcoal molding machine which can successive deal with material until finishing molding charcoal products. The raw materials of finishing molding charcoal products come from wood, coconut shell, bamboo, straw, grain shell and so on.

If you are interested, please contact me any time. We will offer you more information.

Whatsapp: 008613598814777