Rotary shisha charcoal machine is the high-tech efficient shisha charcoal machine, it can press the mixed charcoal powder into two kinds of shape, cubic and round tablets. Below is the operation manual of rotary shisha charcoal machine.

1,Connect the power cable

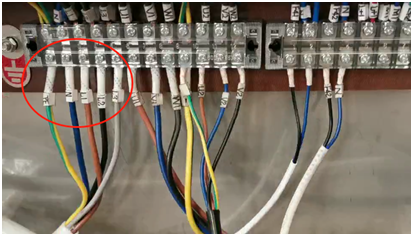

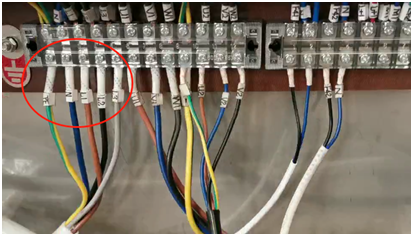

connect the power cable connector to the letter corresponding to the power distribution cabinet according to the letter, as shown in Figure 1.

2,Connected to the host line

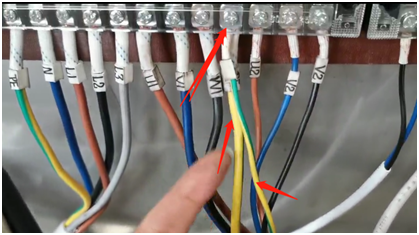

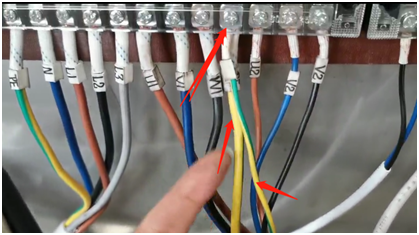

the thickest black line is the host line, the second black line is the loading motor line, the whiteest thin line is the oil pump line, in turn according to the marked letter, in turn linked to the letter corresponding to the power distribution cabinet From left to right, the main line, the loading line, the oil pump line, the feeding and the ground line of the oil pump line (yellow) are connected to a joint as shown. Remember to connect in order to avoid motor reversal.

3, After the wiring is completed

install the small operation cabinet and the main distribution cabinet. The line is long enough. According to the convenience of the site, arrange the position of the small operation cabinet. The small operation cabinet and the main distribution cabinet have four black sockets. Connect the plugs at both ends of the line to the corresponding sockets, which correspond to large ones and small ones. After the installation is completed, try the power supply. The direction of the main unit and the loading direction should be clockwise. Pay attention to the direction of the motor rotation when wiring. It must be in the same direction as the arrow on the machine. Do not reverse it. (refer to 4 in the boot sequence)

4, staring the machine

A, power on

B, the right wall button of the main power distribution cabinet is turned on,

C, operate the small empty operation cabinet host button to open,

The left display shows the main engine speed, adjust the speed to 5.5r/min or more, and slowly increase to 12r/min.

The first time it is adjusted to 5.5r/min, the machine has a memory protection function. Once the host speed is below 5.5r/min, the machine automatically stops operating.

Remark: When the equipment is running in the running-in period, the main engine speed should not be higher than 70% of the maximum speed (20r/min) of the standard. It is about 12r/min or 13r/min. The running-in period: continuous operation for less than 1000h, more than 1000 hours, it can run normally. , 16-17r/min.

D, the loading button is turned on, then adjust the speed button, directly adjust to the highest value of 60.

E, the oil pump button is turned on.

F, the oil pump on the main engine is manually oiled, the green button on the oil pump, after starting the machine every morning, the manual operation is pressed three times, mainly to supply oil to the oil level of the machine rail. Then you don’t have to manually oil it in one day.

G, Put the prepared raw materials into the feeding port and feed them at a constant speed.

Observe the discharge condition. If the pressure is not enough, you can press the manual pressure. There are two handwheels under the feed port. The left hand wheel is for increasing and decreasing pressure, and the right hand wheel is for increasing or decreasing the weight. According to the icon, + is the boost / gain, - is the buck / weight reduction.

Hongrun rotary shisha charcoal machine have been exported to United States, Pakistan, Mongolia, Russia, South Africa, Middle East, Turkey, Malaysia, India, and European Union. For more information, please view our website or contact us via the following Email.

Related Product: Rotary Shisha Charcoal Machine

E-mail: sales@cnhrmachinery.com